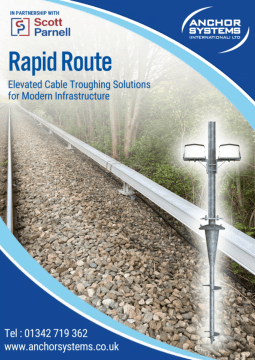

Rapid Route

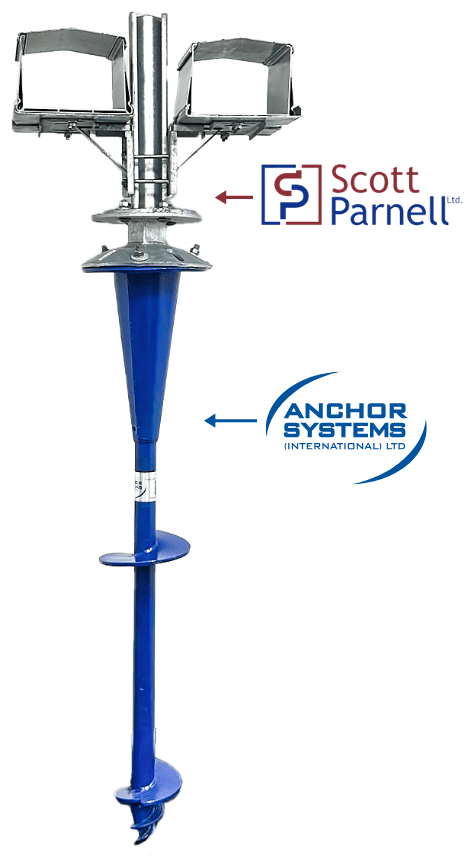

A Joint System with Scott Parnell

A Joint System with Scott Parnell

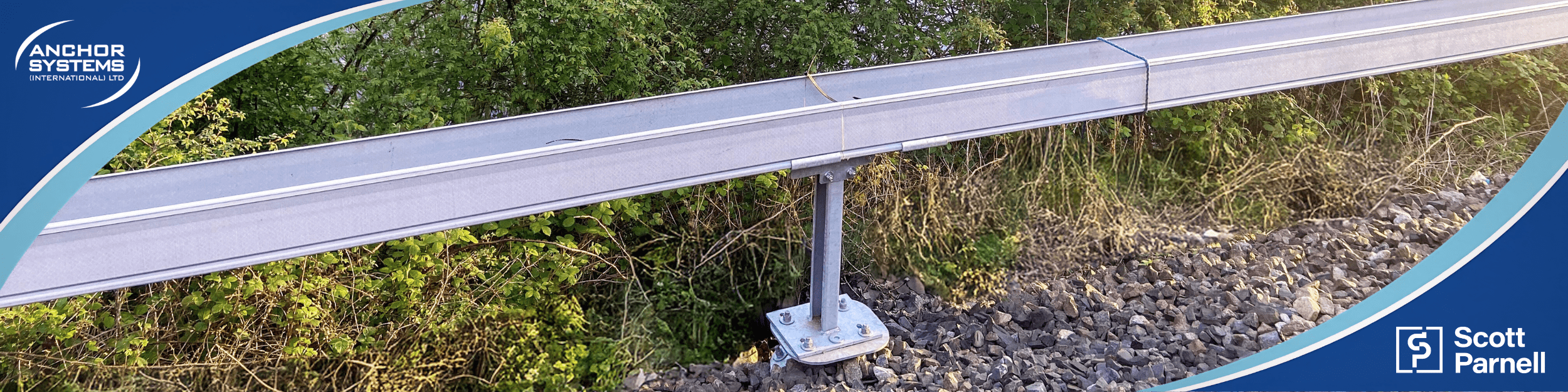

Born from collaboration between Scott Parnell and Anchor Systems International, Rapid Route unites two proven engineering innovations—ARCOSYSTEM® and the Anchor Screw®—to create a game-changing, fully elevated cable route solution for the UK rail and infrastructure sectors.

In a market where traditional options rely heavily on ground-based routing or concrete foundations, Rapid Route is a step forward: the only concrete-free, UK-manufactured, elevated cable route system. This pioneering solution offers rapid, safe, and sustainable installation without compromising durability or performance.

Designed for speed and simplicity, Rapid Route can be installed entirely by hand with no need for excavators, cranes, or heavy plant. Installation rates of over 744 metres in a single shift have already been achieved, dramatically cutting project timelines and labour costs. The system also boasts significant carbon savings, reducing embodied emissions by up to 73% compared to traditional methods.

Whether it’s cost, speed, safety, or environmental responsibility, this is the elevated cable troughing solution the industry has been waiting for.

Key Benefits:

- No concrete or spoil removal required

- No water or any wet trades

- Rapid installation with minimal environmental disruption

- 100% system tested during installation

- Lightweight and modular

- Removable & Reusable

- 100+ year design life

- Designed for all displacable ground types

- Handheld Installation

- PADS approved

- UK-manufactured from recycled materials

Why Choose Rapid Route?

When planning and delivering infrastructure projects, speed, safety, cost-efficiency, and sustainability are more critical than ever. That’s where Rapid Route stands apart. Here’s why leading contractors and asset managers are choosing it:

- Faster Installation: Rapid Route lives up to its name. With no need for concrete, excavation, or heavy machinery, installation is fast and efficient. All components are lightweight and can be installed by hand—allowing for up to 744 metres of system to be deployed in a single 5-hour shift. That’s significantly faster than traditional ground or concrete-based alternatives.

- Environmental Responsibility: Manufactured in the UK using recycled materials—including Anchor Systems’ patented Anchor Screws—Rapid Route is a low-carbon alternative to concrete systems. In fact, it offers a 73% reduction in embodied carbon, making it the sustainable choice for forward-thinking infrastructure projects.

- Cost-Effective: Reduced labour hours. No plant hire. Minimal ground preparation. By eliminating the need for wet trades and heavy groundwork, Rapid Route dramatically reduces both direct and indirect costs. It’s a smarter use of budget across planning, materials, installation, and maintenance.

- Ideal for Challenging Terrain: Adaptable to various terrains, including embankments, uneven ground, and urban environments. The system can be easily modified to fit specific project requirements, whether for standard infrastructure or more complex rail installations.

- Low Maintenance: Built with corrosion-resistant materials and a robust design, the Rapid Route System requires minimal maintenance, reducing long-term operational costs. The galvanised steel components ensure durability even in harsh environmental conditions.

- Safety by Design: With elevated, visible cable routing and reduced need for excavation, Rapid Route significantly lowers on-site hazards. The modular, hand-held installation process also reduces the risk of injury from manual handling and plant-based operations.

DESIGN & PERFORMANCE

Rapid Route P05:

Rapid Route P05:

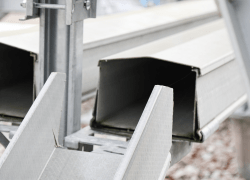

Designed for Heavy-Duty Rail Infrastructure

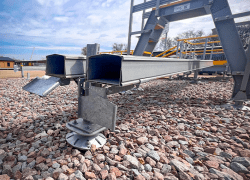

P05 is engineered for applications requiring maximum load capacity and structural flexibility, particularly in extreme sloping or high-load rail environments.

Key Features:

- Includes interface plate for complex, heavy-duty configurations

- Withstands very high loads

- Sigma post and ARCO system installed separately

- Installation time approx. 5-6 minutes per unit

- Ideal for complex rail infrastructure and elevated designs

- Up to 7° alignment

Rapid Route P06:

The New Standard

P06 is now the default foundation system in the Rapid Route range. It delivers high performance while dramatically reducing cost and complexity.

Key Features:

- Interface plate removed to streamline design

- Direct mount Sigma post integrated into the foundation

- Lightweight components allow for 4-5 minute installation per unit

- Up to 50% system cost reduction in comparison to the P05 system

- Suitable for standard infrastructure, embankments, and sloping ground

- Up to 4° alignment

Sustainability Impact

At Anchor Systems, sustainability is at the heart of everything we do. Through continuous innovation, we’re helping to transform how infrastructure is built—offering low-impact, high-performance alternatives that actively reduce environmental harm across the rail network.

Sustainable by Design

Our systems are designed to minimise waste, reduce material use, and eliminate the need for concrete, which significantly lowers carbon emissions during installation. The Anchor Screw and Rapid Route systems not only simplify groundworks—they actively support your environmental targets.

Environmental Impact at a Glance

- Material Efficiency: 89.4% material savings through optimised design

- Carbon Reduction: 73% reduction in embodied carbon, equivalent to 13,920 kg CO2

- Eco-Friendly Manufacturing: Produced from 100% recycled steel in the UK, minimising environmental impact.

- Sustainable Practices: Recyclable components, reduced water usage, and eco-friendly packaging materials.

Greener Materials, Smarter Packaging

Every aspect of our operation is being refined to reduce impact—from recyclable packaging and reduced water usage, to waste management and transport efficiency.

We hold the Made in Britain accreditation and are proud to contribute to a lower-carbon future for the UK’s rail infrastructure.