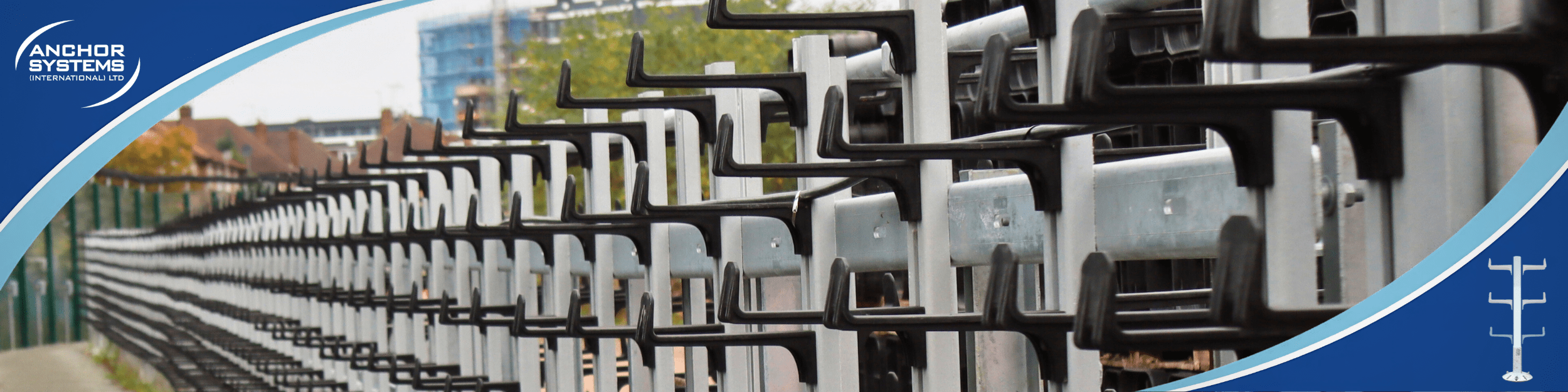

Cable Route Management System

System Overview

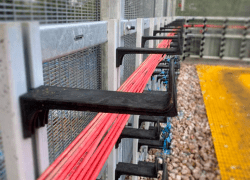

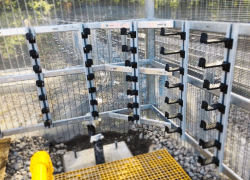

Anchor Systems’ Cable Route Management System (CRMS) offers a bespoke engineering solution designed to revolutionise cable management in challenging infrastructure environments. This innovative system offers unrivalled flexibility, efficiency, and sustainability for complex cable routing challenges across multiple industries, with a particular focus on the rail network.

Our CRMS provides an advanced approach to cable infrastructure, capable of addressing the most demanding installation requirements with remarkable versatility. Designed and engineered to overcome traditional limitations, the system delivers a comprehensive solution that is quick and easy to install, from the Anchor Screw foundations through to the Cable Hangers.

Key advantages of the CRMS include:

Exceptional Installation Efficiency

Exceptional Installation Efficiency - 60% faster foundation installation compared to traditional methods.

- Suitable for challenging ground conditions, tight spaces, and sloping terrain.

- Significant Cost Savings

- 40% cost reduction, with savings increasing per metre installed.

- Lower costs due to reduced man-hours, no plant requirements, and shorter operational possession times.

- Outstanding Environmental Credentials

- 73% reduction in embodied carbon (Hither Green study).

- 13,920 kg CO2 savings per installation.

- 89.4% material efficiency with 100% UK-manufactured materials.

- Advanced Technical Specifications

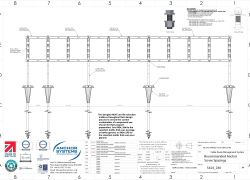

- Supports up to 8 cable runs per side (16 total).

- Anchor Screw spacing up to 2.4m, cable post height up to 2.4m.

- Superior Design Flexibility

- Available in standard steel and GRP non-conductive variants.

- 7° angular adjustability in Anchor Screws for easier installation.

- 50mm horizontal and 30° angular tolerance in H-Rails for flexibility around existing assets.

- Comprehensive Safety Features

- No on-track plant or water required for installation.

- Reduces HAVS risk, noise pollution, and installation hazards.

- Touch-safe system options available.

- Premium Material Quality

- S275 steel grade, galvanised to BS1461 standard.

- 100% recycled materials, manufactured in Britain.

DESIGN & PERFORMANCE

Our Cable Route Management System (CRMS) is a PADS-approved, concrete-free solution designed to provide efficient, durable, and low-maintenance cable management across various rail and infrastructure projects. With installations in over 100,000 locations, including major Transport for London (TfL) projects such as 4LM, PLU, JNP, and Deep Tube, our system has a proven track record in delivering reliable and long-term performance.

Key Benefits

- Industry Approved – One of the only concrete-free systems approved for use on TfL projects.

- Proven Performance – Installed across major railway and infrastructure projects, demonstrating exceptional reliability in demanding environments.

- Fast and Efficient Installation – Designed for rapid deployment with minimal ground disruption, significantly reducing installation time compared to traditional methods.

- Versatile and Scalable – Adaptable to various ground conditions and cable load requirements, ensuring suitability across different project needs.

- Sustainable and Cost-Effective – Eliminates the need for concrete foundations, reducing environmental impact and project costs.

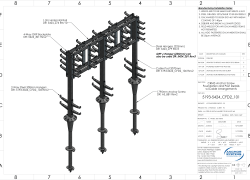

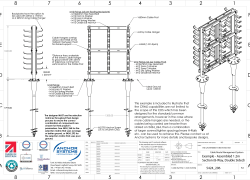

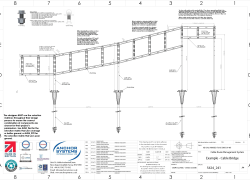

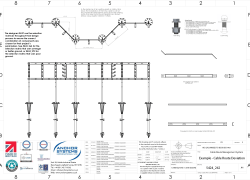

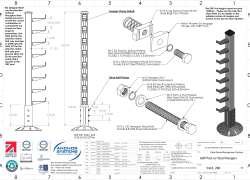

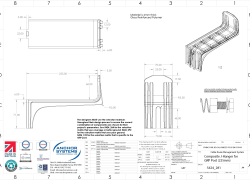

System Design and Components

Our CRMS integrates key components designed for structural integrity and adaptability:

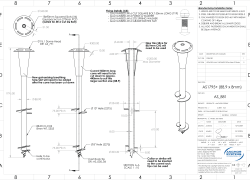

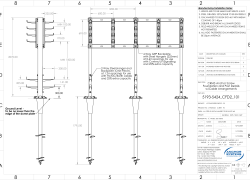

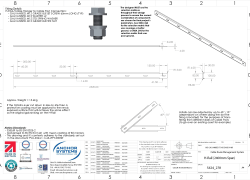

- Anchor Screws – Selected based on ground conditions, cable load, and project-specific requirements, providing a secure and reliable foundation without the need for concrete.

- Cable Posts – Available in heights ranging from 1050mm to 2400mm, with robust steel construction to support varying cable loads.

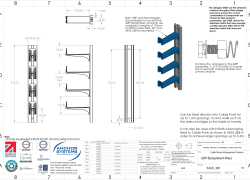

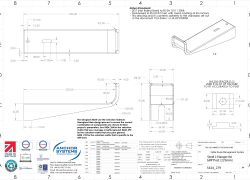

- Horizontal Rails (H-Rails) – Adjustable and available in multiple lengths (600mm, 1200mm, 1800mm, and 2400mm), ensuring flexibility in cable placement and additional mounting support.

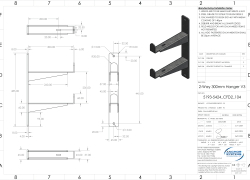

- Cable Hangers – Offered in different sizes (145mm, 170mm, 225mm, and 300mm) with a minimum 100mm spacing, allowing for easy cable loading and organisation.

- J-Hangers – Available in composite (fully non-conductive) or steel (cost-effective, partially touch-safe) options, ensuring suitability for different operational environments.

By combining these components, the CRMS provides a robust, adaptable, and maintenance-friendly solution that enhances safety, efficiency, and longevity across rail and infrastructure projects.