Sock Anchors

Our Sock Anchor system for stabilisation of damaged masonry structures, provides an ideal solution for heritage applications, listed building renovations and refurbishment projects where appearance and planning constraints need to be considered. They offer a completely concealed top termination to preserve the original appearance of a structure.

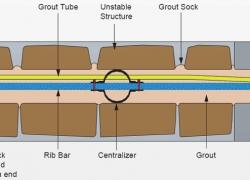

The system comprises a high strength stainless steel Rib Bar surrounded by a woven elastic polyester Grout Sock, sealed at both ends, which is inserted into a pre-drilled hole in the structure. Grout is injected into the Grout Sock – which acts as temporary shuttering, for the grout, while it expands to tightly fit the contours of the pre-drilled hole to form a strong mechanical and chemical reinforcement.

The woven fabric of the sock allows the water to pass through and form an intimate chemical bond with the surrounding structure. Once cured the grout and Rib Bar become a permanent integral part of the structure adding strength, rigidity and stability. A small section of the Rib Bar is left exposed to allow attachment of load plates and/or proof testing equipment. Once testing is complete the bar end may be concealed below the surface of the structure

Where a structure contains sharp, loose or granular fill a reusable solid sleeve may be used to protect the Grout Sock during insertion.

DESIGN & PERFORMANCE

- Simple installation

- Saves on grout and other materials

- High strength

- Made to any length

- Available to fit up to 90mm core hole

- Testing plant readily available

- Offers anchorage into rock