Rapid Route – Kennishead Line

- CLIENT : SPL Powerlines UK

- CONTRACTORS : SPL Powerlines UK

- INSTALLER : Anchor Systems International Ltd / Scott Parnell

- INSTALLER : Westlin Group

REQUIREMENT

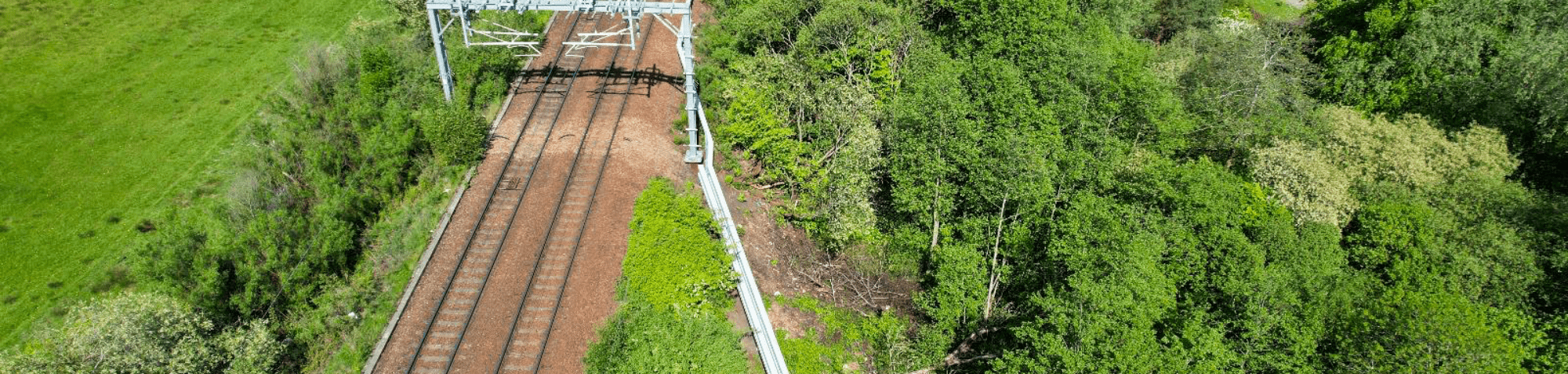

SPL Powerlines UK, the client for this project, was undertaking a significant upgrade of Overhead Line Equipment (OLE) across a section of the Kennishead line in Scotland. In conjunction with these works, a nearby substation was also being refurbished. A key obstacle encountered during planning was the inability to use traditional concrete-based drainage solutions. The proposed cable route featured steep gradients and complex intersections where multiple cables emerged from the substation to join the OLE. These physical conditions rendered conventional ground troughing both impractical and cost prohibitive.

Given the steep and uneven terrain, a lightweight, high-capacity alternative cable management solution was required — one that could be installed with minimal ground disruption and still provide secure and reliable support for vital cabling infrastructure.

SOLUTION

Anchor Systems International Ltd was engaged to provide a solution using its Rapid Route Cable Management system — a lightweight, high-capacity alternative to traditional ground troughing, designed specifically for complex or steep environments. This project marked the first installation of Anchor Systems International Ltd’s new streamlined Rapid Route system, incorporating an updated Anchor Screw design for improved performance and versatility.

Two types of anchor screws were used: the AS1595 and AS1795 models, chosen based on the site’s load requirements and ground conditions. A total of 34 anchor screws were installed using a combination of handheld 400-inch torque heads and a machine-mounted 600x excavator torque head. A quick-coupling mechanism allowed the torque head to be mounted on a compact excavator, facilitating installation in confined areas with restricted access.

The original design specified 4 cable troughs per post but spaced at intervals of 5-6 metres instead of the recommended 3 metres. This issue was identified and rectified on-site through a design amendment, ensuring consistent support and compliance with project requirements.

Pre-installation desktop studies were conducted in place of on-site testing, and the installation methodology involved standard procedures for anchor screw deployment, including the use of hydraulic power packs, reaction arms, and hex drive adaptors for securing the system.

Outcome

Despite challenging site conditions — including restricted access, heavy vegetation, muddy terrain, and persistent rainfall, the project was successfully completed. Careful planning and responsive problem-solving enabled the team to overcome access limitations and safety risks such as slips and trips on wet slopes.

The revised design, along with the performance of the new Anchor Screw systems, resulted in a durable and stable Rapid Route Cable Management installation. This project not only demonstrated the adaptability of Anchor Systems International Ltd’s solutions in non-standard environments but also served as a successful first use of the updated anchor screw range in a live railway infrastructure setting.

Anchor Systems International Ltd delivered a robust, efficient, and cost-effective solution that met the client’s objectives while adapting to the complexities of the site.